Jun 11,2025

Tsinghua team collaborates with enterprises to successfully develop ultra large caliber and ultra-high pressure corrosion-resistant wedge gate valves

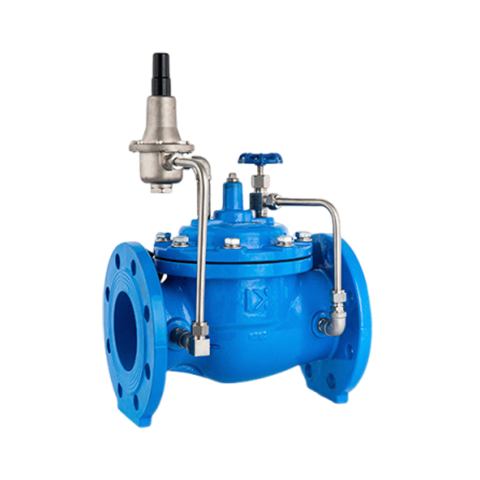

Get Quote NowIn recent years, the demand for high-performance industrial valves has surged, driven by the rapid development of various sectors, including oil and gas, chemical processing, and water management. Among the critical components in these industries, wedge gate valves stand out for their ability to provide reliable sealing and flow control under extreme conditions. In a groundbreaking achievement, a team from Tsinghua University has collaborated with leading enterprises to develop ultra-large caliber and ultra-high pressure corrosion-resistant wedge gate valves. This article delves into the significance of this development, the collaborative efforts involved, and the potential impact on the industry.

**The Need for Advanced Wedge Gate Valves**

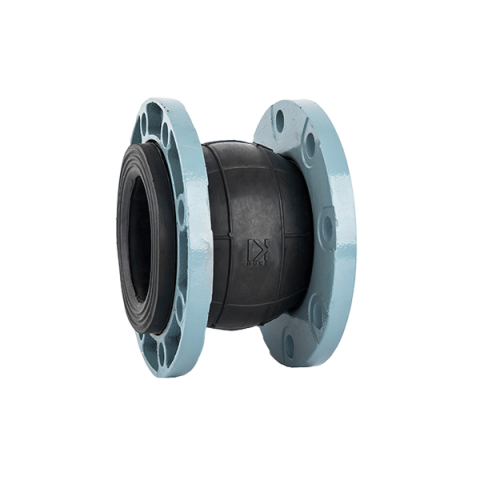

Wedge gate valves are essential in applications where a tight seal is required to prevent leakage. Traditionally, these valves have been used in various industries; however, the increasing complexity of industrial processes has created a demand for valves that can withstand higher pressures and corrosive environments. Ultra-large caliber valves, in particular, are necessary for managing large volumes of fluids, making them indispensable in sectors such as oil and gas extraction, chemical manufacturing, and water treatment.

The challenge lies in creating valves that not only meet these specifications but also maintain durability and reliability over time. Corrosion resistance is particularly crucial, as many industrial environments expose valves to harsh chemicals and extreme temperatures. Recognizing these challenges, the Tsinghua team aimed to innovate and improve existing designs, resulting in the development of advanced wedge gate valves.

**Collaboration Between Academia and Industry**

The successful development of these advanced wedge gate valves was made possible through a strategic collaboration between Tsinghua University and several key enterprises in the valve manufacturing sector. This partnership brought together the university's cutting-edge research capabilities and the practical expertise of industry leaders.

The collaboration began with a series of workshops and brainstorming sessions, where engineers and researchers exchanged ideas on the design and material selection for the new valves. Tsinghua's team leveraged its expertise in materials science and mechanical engineering to identify suitable corrosion-resistant alloys and coatings. The enterprises contributed their knowledge of manufacturing processes, ensuring that the valves could be produced efficiently and at scale.

This synergy between academic research and industrial application is a prime example of how collaboration can drive innovation. By pooling resources and expertise, the Tsinghua team and their partners were able to tackle the technical challenges associated with developing ultra-large caliber and ultra-high pressure valves.

**Key Innovations and Features**

The newly developed wedge gate valves incorporate several key innovations that set them apart from traditional designs. Firstly, the valves are constructed using advanced corrosion-resistant materials, which significantly extend their lifespan in aggressive environments. The use of specialized coatings further enhances their durability, ensuring reliable performance even under extreme conditions.

Secondly, the design of the valves has been optimized for high-pressure applications. This includes reinforcing critical components to withstand the stresses associated with high-pressure fluid flow. The Tsinghua team utilized advanced computational fluid dynamics simulations to analyze flow patterns and optimize the valve geometry, resulting in improved flow characteristics and reduced pressure drop.

Moreover, the valves are designed with a user-friendly operation mechanism, allowing for easy installation and maintenance. This feature is particularly beneficial for industries where downtime can lead to significant losses. The collaboration also focused on ensuring that the valves meet international standards for safety and performance, making them suitable for global markets.

**Impact on the Industry**

The successful development of these ultra-large caliber and ultra-high pressure corrosion-resistant wedge gate valves is poised to have a significant impact on various industries. By providing a reliable solution for managing fluids in challenging environments, these valves can enhance operational efficiency and reduce maintenance costs for businesses.

In the oil and gas sector, for example, the ability to handle high pressures and corrosive substances will allow for safer and more efficient extraction processes. Similarly, in chemical processing, these valves can help minimize the risk of leaks and improve the overall safety of operations. Water treatment facilities will also benefit from the enhanced durability and performance of these valves, ensuring a consistent supply of clean water.

Furthermore, the collaboration between Tsinghua University and industry partners serves as a model for future innovations. It highlights the importance of combining academic research with practical application to address real-world challenges. This approach can lead to the development of more advanced technologies, ultimately benefiting society as a whole.

**Conclusion**

The collaboration between the Tsinghua team and leading enterprises has resulted in a remarkable advancement in the field of industrial valves. The development of ultra-large caliber and ultra-high pressure corrosion-resistant wedge gate valves addresses critical needs in various sectors, paving the way for safer and more efficient operations. As industries continue to evolve and face new challenges, such collaborations will be essential for driving innovation and ensuring that technological advancements keep pace with demand. The success of this project not only enhances the capabilities of the valve industry but also underscores the value of partnerships between academia and industry in fostering progress.

Related News

Jun 11,2025

The 2025 China International Petroleum & Petrochemical Technology and Equipment Exhibition (CIPPE) has set the stage for industry leaders to unveil their latest innovations.

Jun 11,2025

With its focus on connectivity, data-driven decision-making, and sustainability, Tun Valve is not just adapting to change; it is leading the charge toward a smarter, more efficient manufacturing future.

Jun 11,2025

In the competitive landscape of manufacturing, innovation is the key to survival and success.

Let us know your requirement. We will offer best products & service to you

Our expert team will provide you with personalized solutions.

Fill out the form to enjoy exclusive one-to-one service and quick resolution of your needs.

Send your message to unlock more practical resources and industry knowledge.

Distributor Following

Welcome same-minded global partners to expand your local market together!

You need to meet the following conditions:

1. Some experience in the Building Materials Industry

2. There are certain sales channels available

3.Love and decide to explore the local market together

Whatsapp: +86 18929508784

E-mail:duke_value@163.com

Welcome to leave a message!