Dec 02,2020

Where should industrial valves go? Thoughts on the future of valves

Get Quote NowMany valve manufacturers are seeking new possibilities, perhaps seeing new opportunities presented by this year's pandemic; they are no longer content with merely meeting the basic requirement of maintaining the normal flow of liquid media. How can valves enter the era of Industry 4.0?

As early as 2018, industrial valve manufacturers were navigating between fear and hope. Sales experienced comprehensive growth in early 2018, yet the international community remained volatile. How did we, as valve suppliers, respond?

Like other industries, the valve industry recognizes the opportunities and challenges presented by Industry 4.0. For companies in the valve industry, optimizing corporate structure and improving customer relationships is crucial. This is not only to cope with increasing price pressures but also to increase and compete for product added value.

The communication technology capabilities of industrial valves can now be a key to a company's management success or failure. From our long-term development, all products should 'talk' to each other within the network and environment of industrial production enterprises. A necessary prerequisite for comprehensive networking is the exchange of data independent of manufacturers and users.

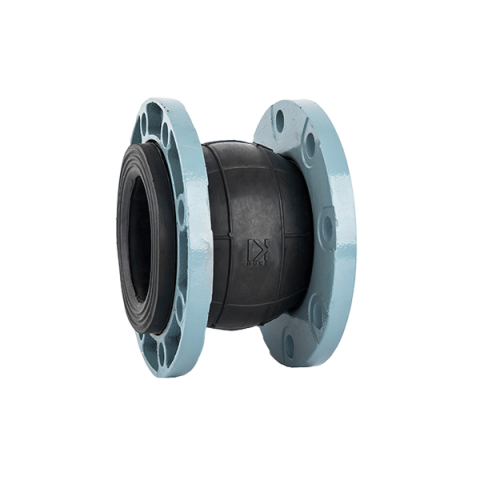

The technology of many explosion-proof electric valves has not been updated. If enterprises want to launch new explosion-proof electric valves, they must have a communication plan to address the breakage of the explosion-proof disc. Usually, the wires responsible for sending signals from the explosion-proof disc are led out from the explosion-proof disc bracket, but this may lead to the problem of poor sealing of the explosion-proof valve. A PyC coating is applied to the surface of the explosion-proof disc, giving it good high-temperature resistance. This is specially designed for process industry enterprises involved in corrosive media during production, suitable for explosion-proof discs used in low working pressure and a temperature range of -180℃ ~1500℃.

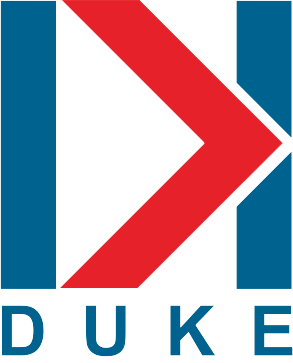

Automation technology ensures that the fluid medium reaches its intended destination. Low-friction and long-life control valves have been developed for industrial valves in the medium and high power range for short-term, emergency, and routine operations. This valve can be used in demanding applications while performing maintenance-free quick opening and closing tasks.

In the context of Industry 4.0, valves are developing into electro-pneumatic technology-controlled automation systems. This allows for economical, rapid, and seamless equipment commissioning and monitoring, enabling timely implementation of wear-driven equipment management and maintenance, minimizing workflow and equipment downtime.

Related News

Jun 11,2025

The 2025 China International Petroleum & Petrochemical Technology and Equipment Exhibition (CIPPE) has set the stage for industry leaders to unveil their latest innovations.

Jun 11,2025

With its focus on connectivity, data-driven decision-making, and sustainability, Tun Valve is not just adapting to change; it is leading the charge toward a smarter, more efficient manufacturing future.

Jun 11,2025

In the competitive landscape of manufacturing, innovation is the key to survival and success.

Let us know your requirement. We will offer best products & service to you

Our expert team will provide you with personalized solutions.

Fill out the form to enjoy exclusive one-to-one service and quick resolution of your needs.

Send your message to unlock more practical resources and industry knowledge.

Distributor Following

Welcome same-minded global partners to expand your local market together!

You need to meet the following conditions:

1. Some experience in the Building Materials Industry

2. There are certain sales channels available

3.Love and decide to explore the local market together

Whatsapp: +86 18929508784

E-mail:duke_value@163.com

Welcome to leave a message!